Trust and Partnership

As an experienced electronics service provider, we offer more than just production and assembly services for your complete assembly. We procure your components, assemble your circuit boards and readily offer you the option for complete outsourcing. With our know-how and many years of experience as an EMS (electronics manufacturing services) provider, we are available to advise you at all times.

Click here for our latest brochure "Electronics² ODM/EMS Services" - just have a look.

Kontron ODM/EMS Alliance – More than just Production and Assembly

Low volume / high mix:

We are also your competent partner for cost-effective production of small and medium quantities

High volume / low mix:

Very large unit quantities are produced by our collaboration partner Ennoconn, a subsidiary of Foxconn

Active site selection:

We produce at the locations that best meets your requirements

Product and cost analysis:

Upon request, we will suggest alternative components and manufacturing processes to reduce costs

Lifecycle analysis and management:

Leverage our forecast data to choose the optimal time for new design or redesign

Global sourcing:

Take advantage of our global purchasing networks

Internal second source:

We offer maximum supply security in the event of a production facility downtime

Manufacturing Expertise

We are well positioned

In addition to regional proximity, we offer a comprehensive portfolio of development and manufacturing services.

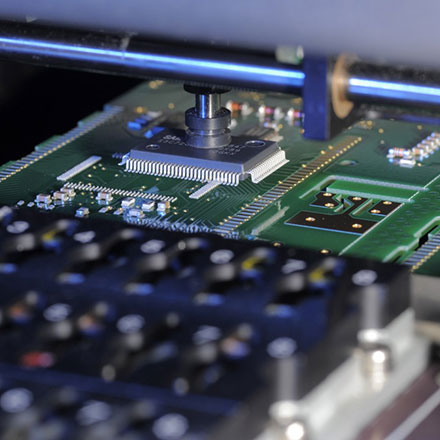

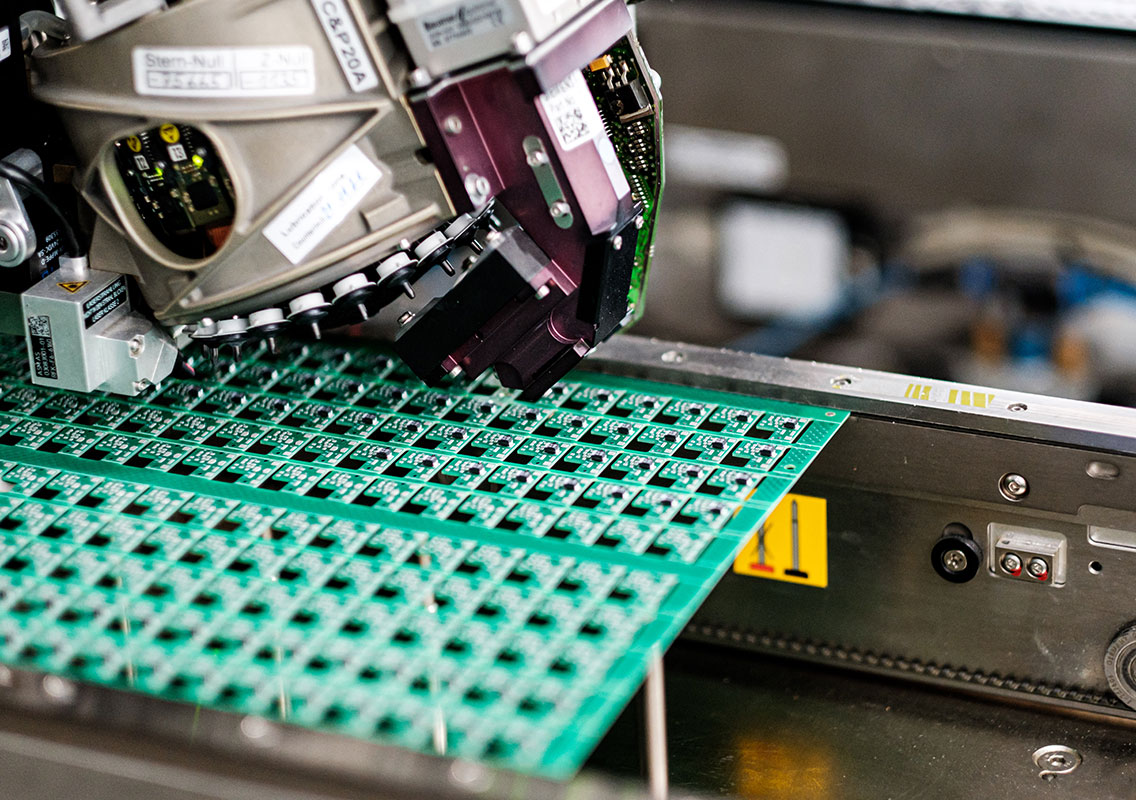

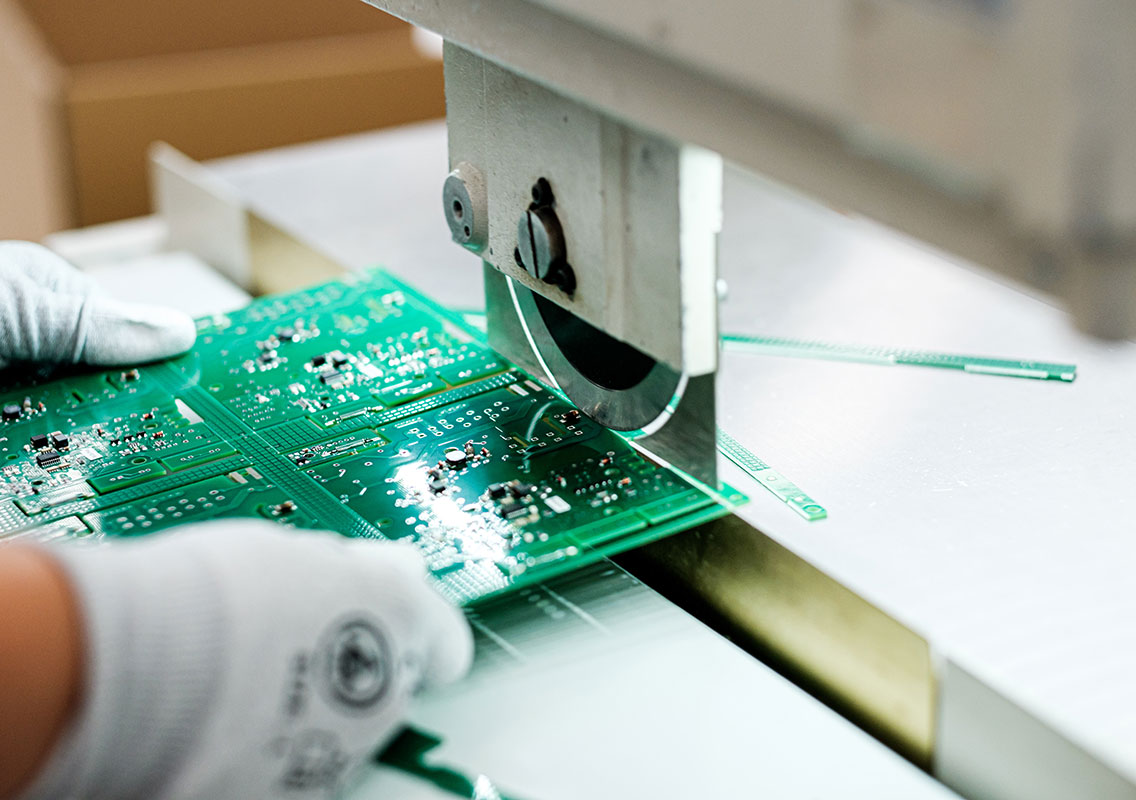

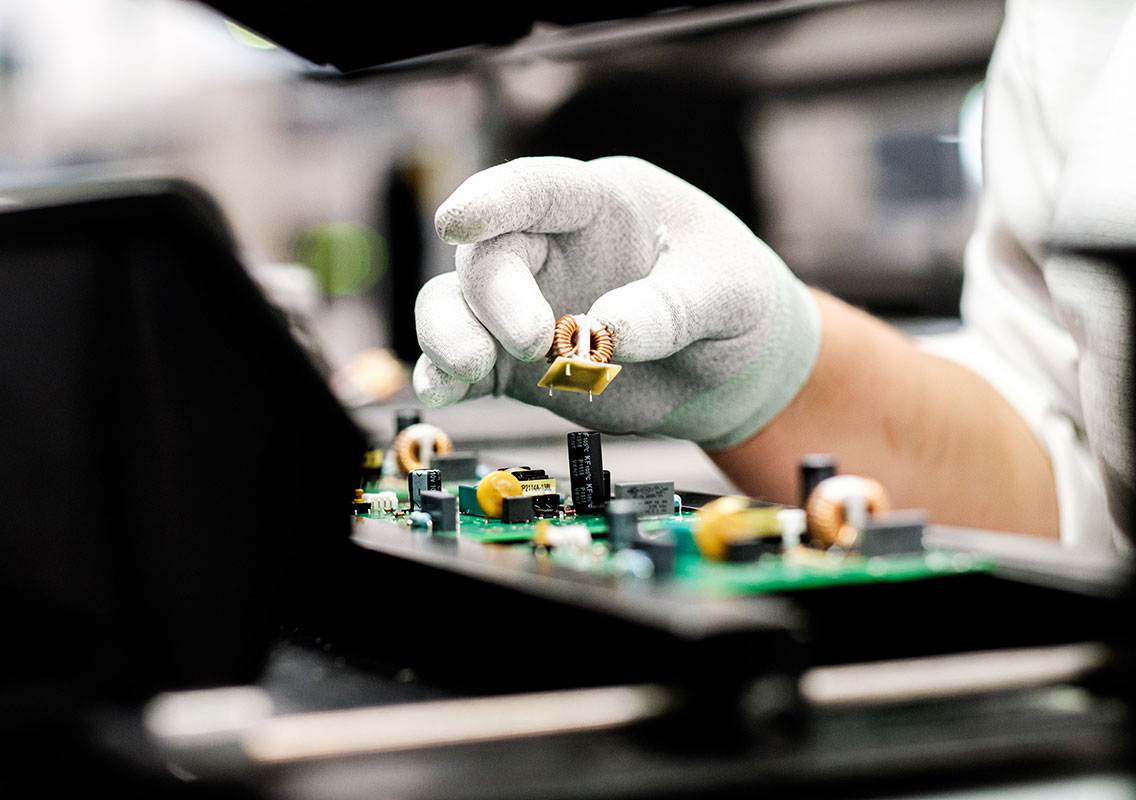

Assembly technologies

- SMT assembly

- THT assembly

Soldering processes

- Reflow soldering

- Wave soldering

- Selektive soldering

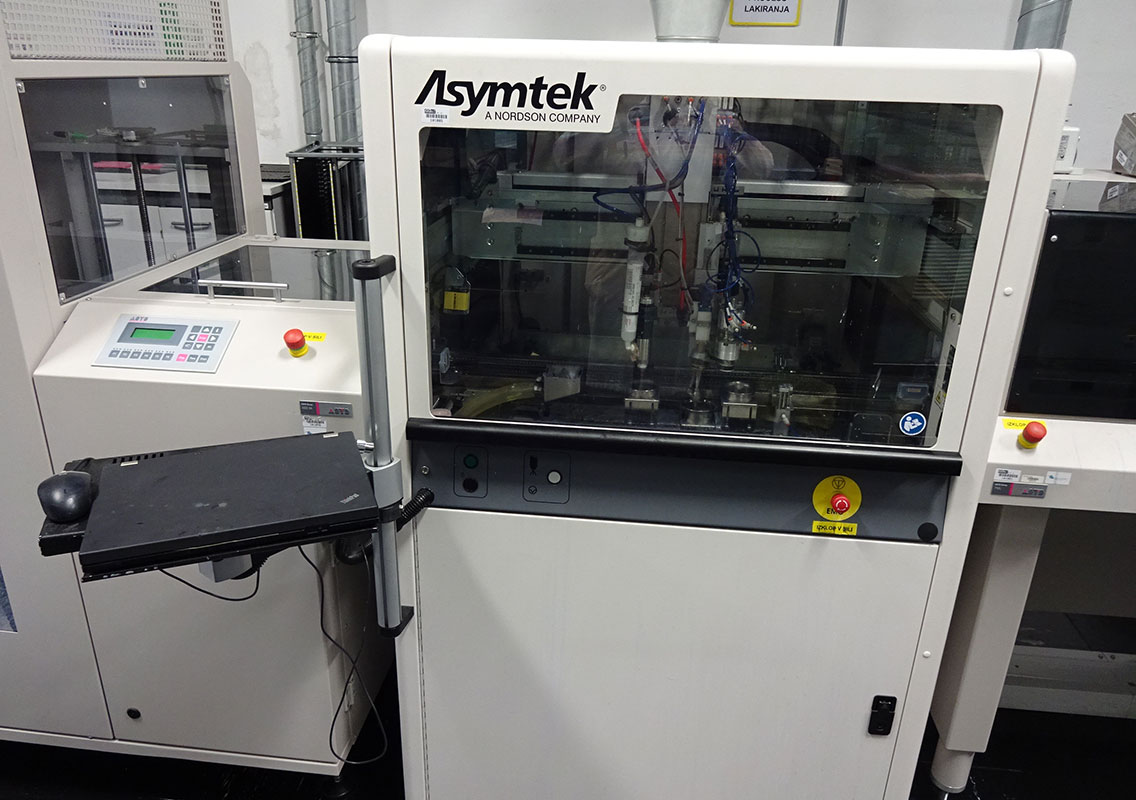

Surface Protection

- Coating to protect against environmental conditions

- Grounting

- Nano coating

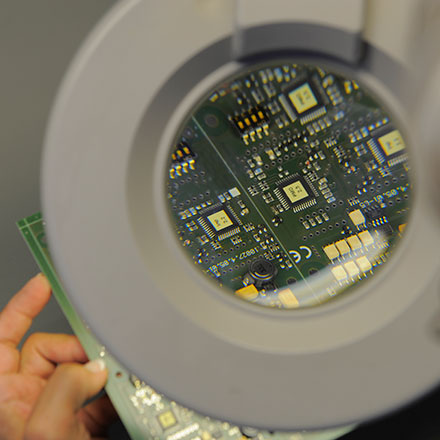

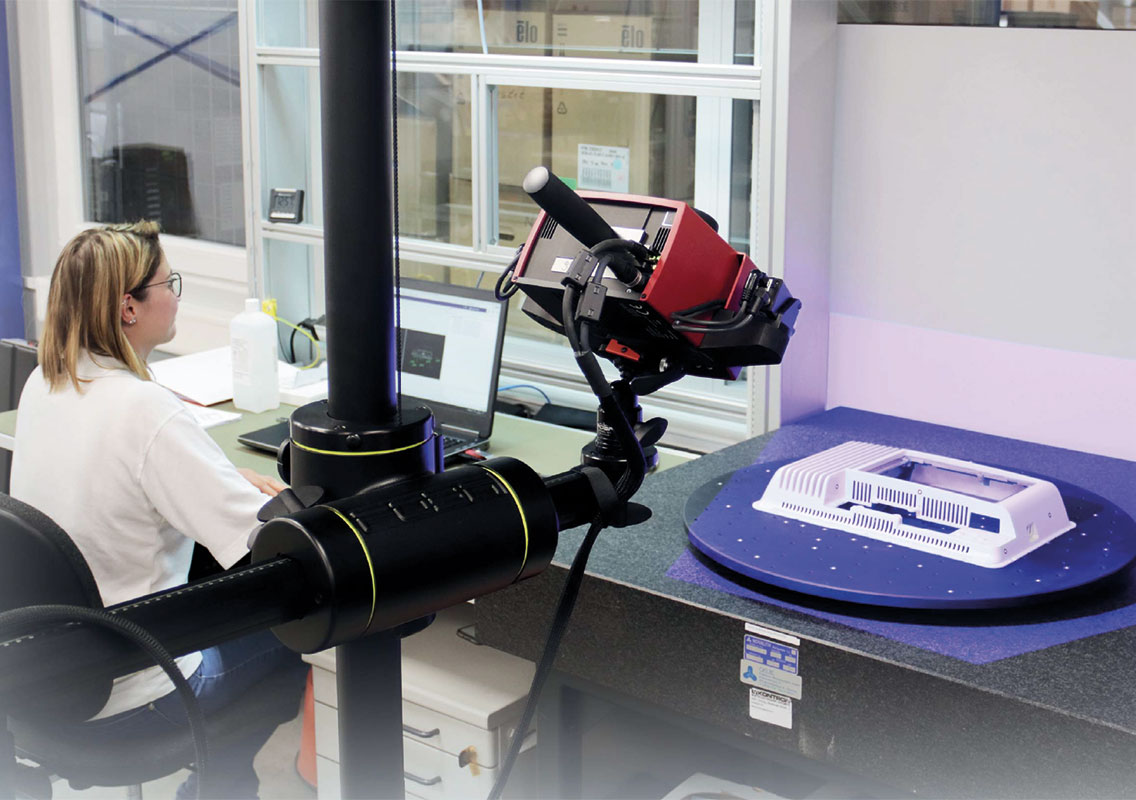

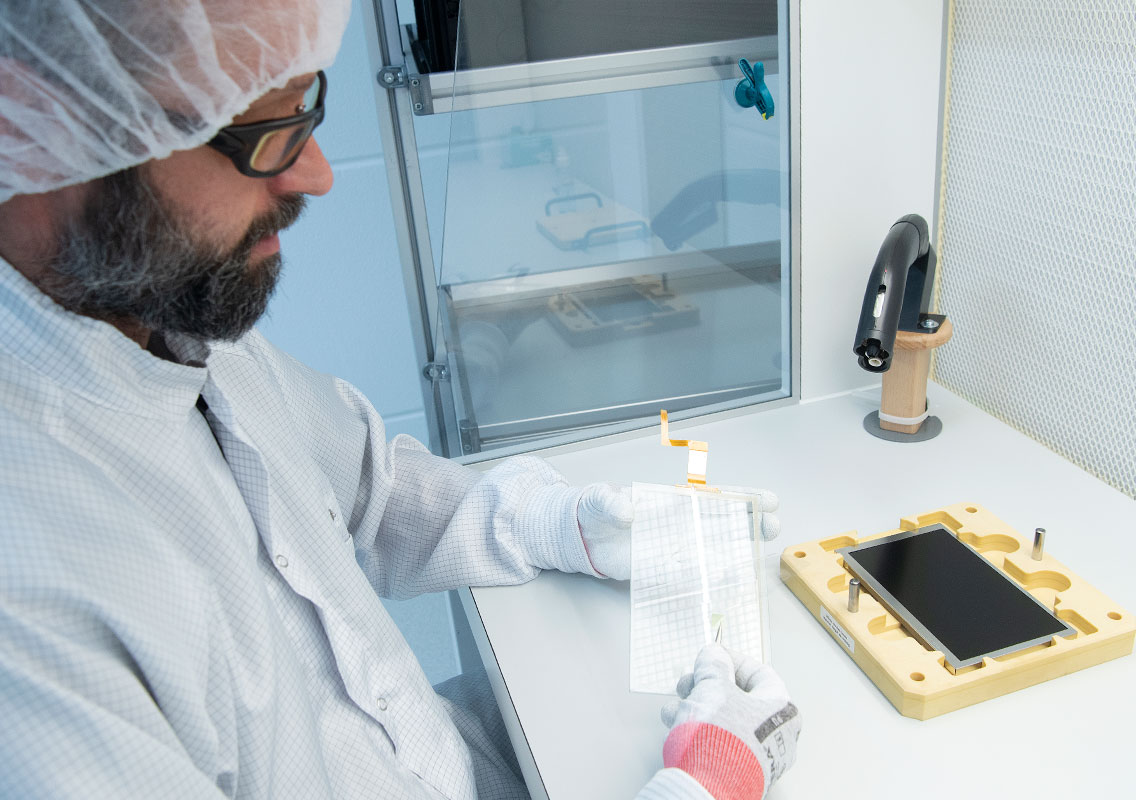

Testing & Quality

Modern technology and the highest quality

All electronic components, modules and systems produced by us are subjected to intensive quality and functional tests.

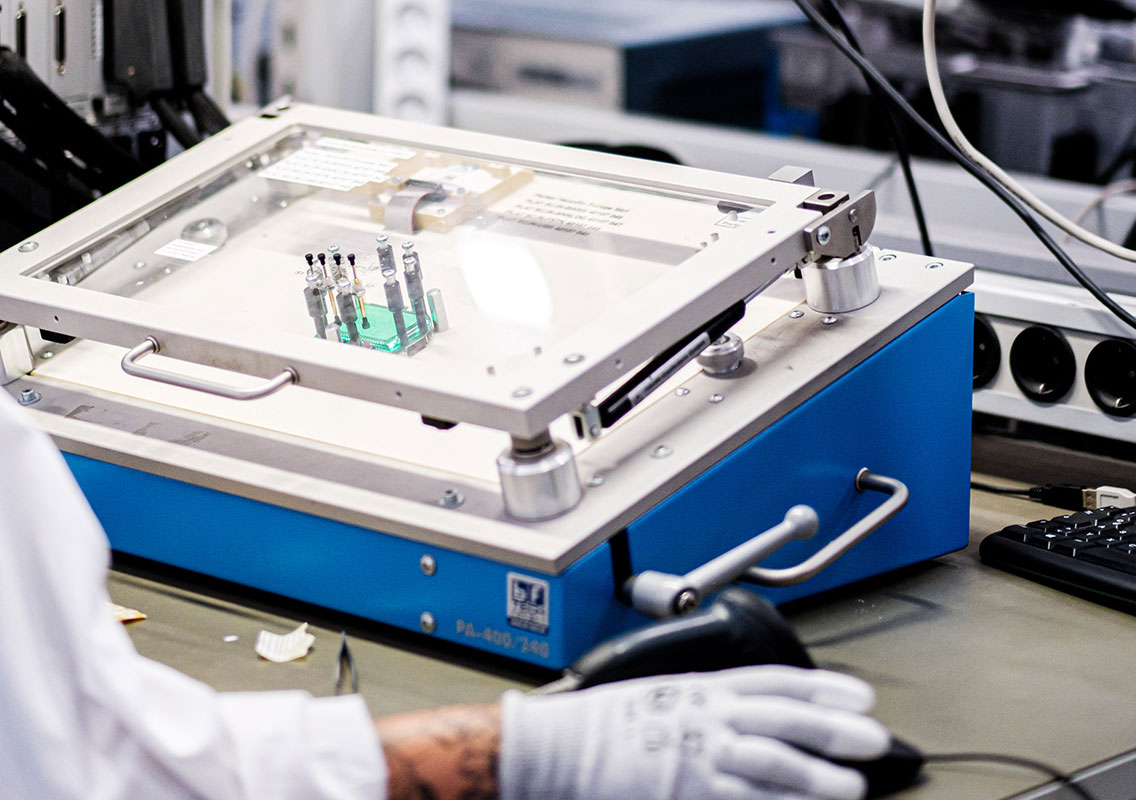

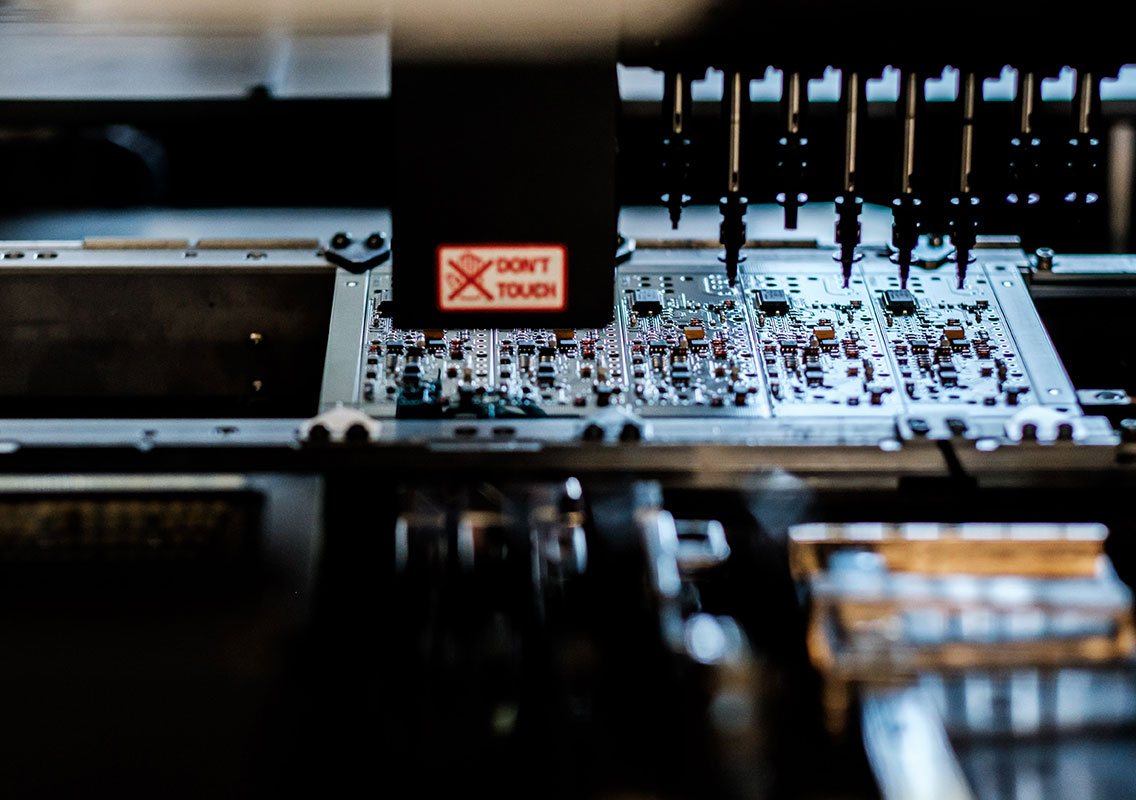

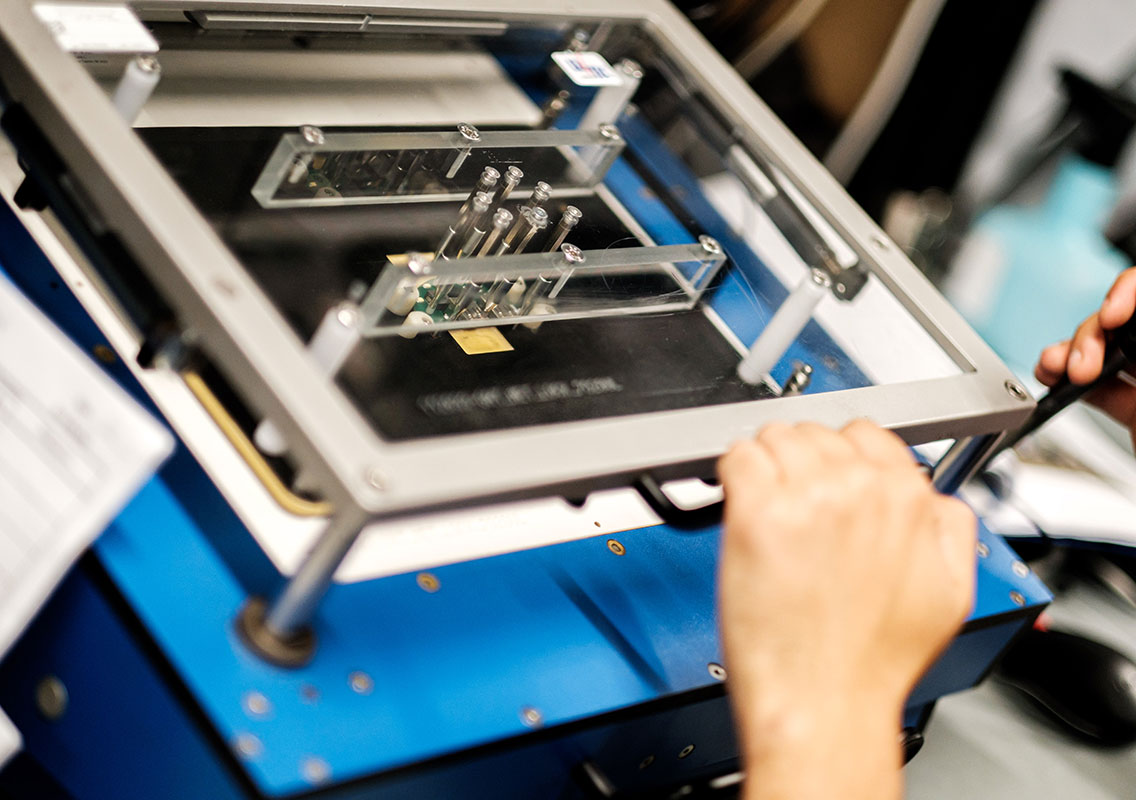

Inline inspection procedures

- SPI Solder paste inspection

- 3D AOI Automated optical inspection

End-of-line testing process

- ICT In-circuit test

- FKT Function test

- BST Boundary Scan Test

- High-voltage test

- X-Ray

Test equipment construction

- Testing according to customer specifications

- Own testing services

- Test software development

Traceability

- Traceability at the component and assembly levels

- Process data monitoring and archiving

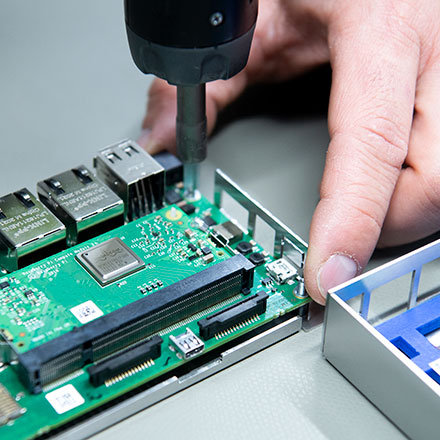

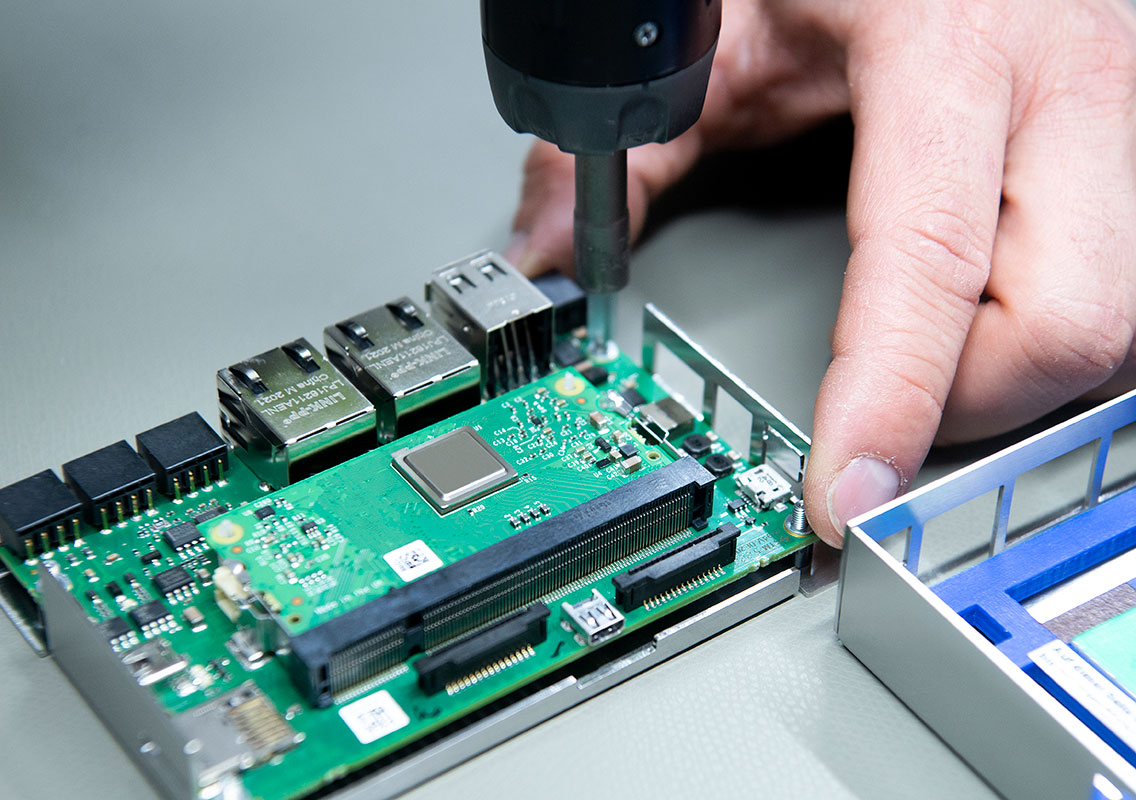

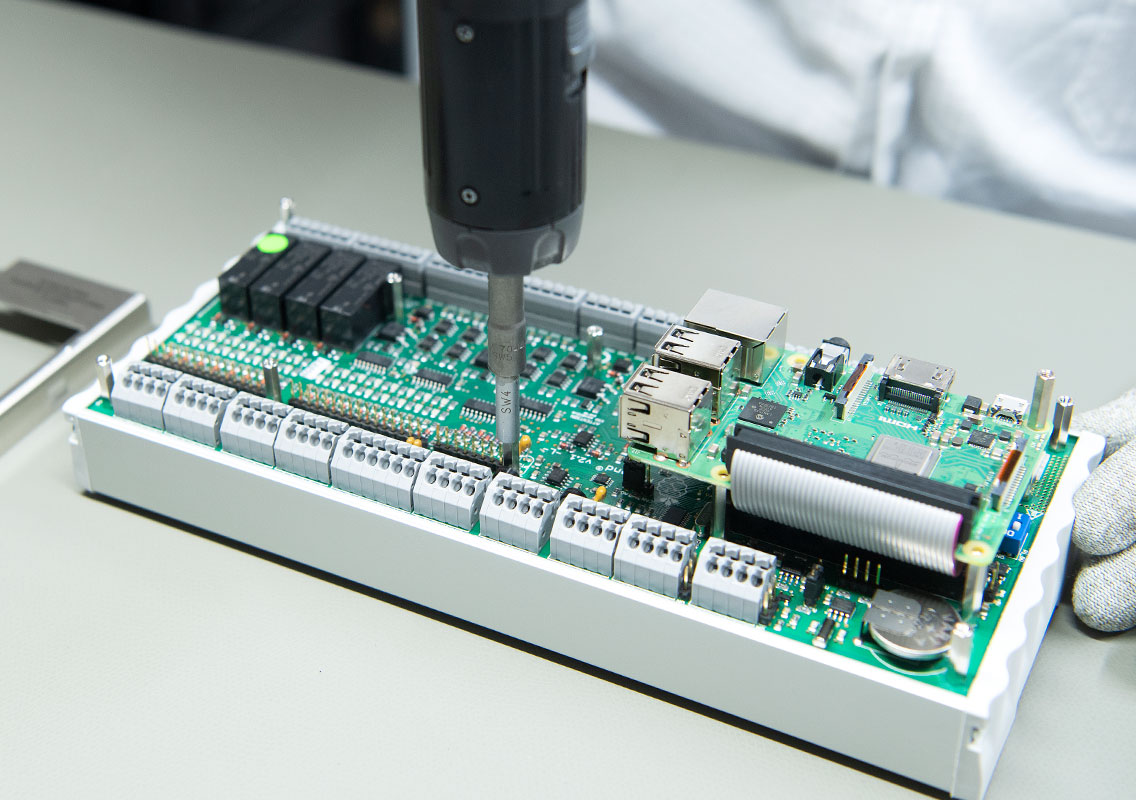

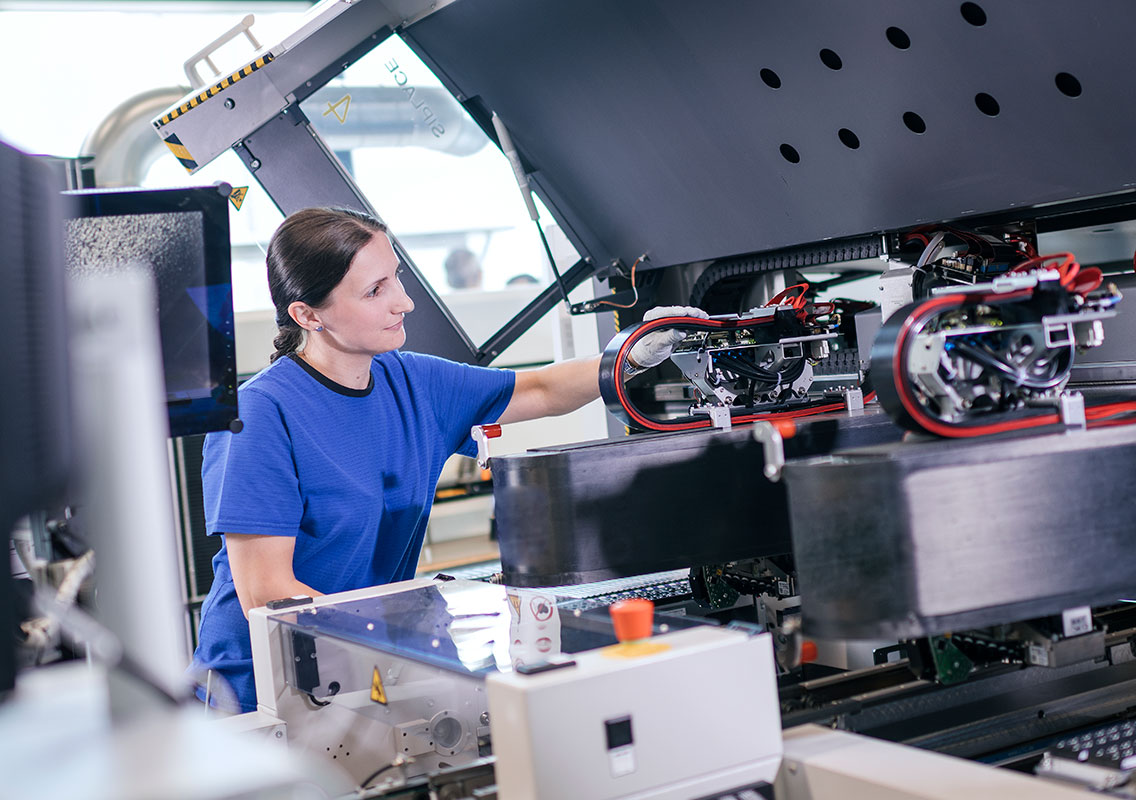

Final assembly

Your partner for complex assembly work

After electrical function test and programming, if desired, we will also carry out complex assembly work on your components and devices.

Final assembly

- System assembly

- Electromechanical components

- Box building

- Machine assembly

Service

Your trust inspires us to reach for new heights

We cover the entire life cycle of electronic components and devices, from consulting and product development to certifications and series production to end-of-life management. In addition, you can take advantage of our global supplier network and our large purchasing volume.

Material management

- Kontron global sourcing (consolidation of demand worldwide and direct price negotiation with the manufacturer)

- Global network of suppliers

- Quality-employees in the most important procurement markets

- Direct support of all leading semiconductor manufacturers

Product life cycle management

- PCN process, EOL monitoring, sourcing, and stocking of discontinued parts

- Search for and testing of alternative components

- Connection to silicon experts

- Long-term storage of components with nitrogen

Supply-chain management to the customer

- Consignment stock for a flexible and needs-based supply

- Kanban

- Rolling forecast

- Security stocks

Repairs service

- Repair in cases of warranty and service

- Technical support